Salesforce Manufacturing Cloud: Visual Insights with AbstraLinx diagrams

October 10, 2024

In today's competitive manufacturing landscape, having the right tools can make all the difference. Salesforce Manufacturing Cloud provides a seamless way to manage your operations and keep customers happy.

To fully capitalize on the power of Salesforce Manufacturing Cloud, it is essential to have a clear understanding of its underlying data architecture. This is where AbstraLinx plays a pivotal role. AbstraLinx provides an advanced solution for visualizing, documenting, and managing the complex data models within Salesforce Manufacturing Cloud

In this blog, we'll explore how AbstraLinx can help you unlock the full potential of this robust platform. Let's dive in and see how it all works!

What is Salesforce Manufacturing Cloud?

Salesforce Manufacturing Cloud is a comprehensive CRM solution designed specifically for the manufacturing industry. It empowers manufacturers to efficiently manage customer interactions and the entire service lifecycle. By promoting collaboration and transparency among sales, operations, and partners, it enables informed decision-making and drives business growth.

For example, consider a company that produces electric cars. Using Salesforce Manufacturing Cloud, they can track all customer activities, such as orders and support requests, in a centralized system. The sales team can collaborate with operations to ensure timely production and delivery while sharing real-time updates. Additionally, the platform's forecasting capabilities help predict demand, optimize inventory, and address supply chain issues, enhancing customer satisfaction and profitability.

Key Features and Benefits of Salesforce Manufacturing Cloud

| Feature | Overview | Benefits |

|---|---|---|

| Sales Management | Tools to manage complex sales agreements, align sales with production, and track commitments. | Streamlines processes and provides real-time sales visibility. |

| Service Management | Integrates with Salesforce Service Cloud to manage the service lifecycle, warranties, and support. | Delivers consistent customer support and proactive issue resolution. |

| Inventory Visibility | Integrates with ERP systems for real-time inventory management across locations. | Optimizes inventory levels and ensures product availability. |

| Account Forecasting | Focuses on demand forecasting at the individual account level. | Enables tailored planning and improves forecast accuracy. |

| Advanced Account Forecasting | Provides deeper insights and granular control over demand planning for key accounts. | Optimizes resource allocation based on detailed account data. |

Salesforce Manufacturing Cloud Data Model

To truly understand and leverage the capabilities of Salesforce Manufacturing Cloud, it’s essential to have a clear view of the underlying data models. These models represent the relationships between various components and processes within the platform, providing a roadmap for how data flows and interacts. With AbstraLinx, we’ve created detailed diagrams that illustrate these data models, helping you visualize and manage the complex architecture of Manufacturing Cloud. (Learn more about this Salesforce cloud)

Below are the key areas we’ve focused on, along with the corresponding data model diagrams:

Generating Model Documentation and a Data Dictionary

AbstraLinx makes documenting your Salesforce Manufacturing Cloud architecture effortless by automatically generating comprehensive data dictionaries and model documentation.

These resources provide clear definitions of data elements and visually map relationships between entities, helping teams quickly understand and manage complex data structures.

With AbstraLinx, you can streamline your Salesforce implementation, reduce errors, and keep everyone aligned.

With AbstraLinx, you can automatically generate:

Model Documentation: Includes entity diagrams, field descriptions, and process flows, offering a visual and textual overview of your Manufacturing Cloud setup.

Data Dictionary: Contains comprehensive details about your data, including definitions, relationships, and security measures.

Explore the capabilities of AbstraLinx and see how it enhances your Salesforce Health Cloud experience. Download the project and start your free trial today!

.

In summary: Salesforce Manufacturing Cloud is a powerful tool for optimizing sales, service, and forecasting in the manufacturing industry. To fully leverage its capabilities, clear data models and documentation are essential. AbstraLinx simplifies this process by providing automated data visualization and documentation, helping teams reduce errors, improve collaboration, and make informed decisions. With AbstraLinx, your organization can confidently implement and scale Salesforce Manufacturing Cloud, ensuring long-term success.

Read more related posts

Subscribe To Our Newsletter

Subscribe to our email newsletter today to receive updates of the latest news, tutorials and special offers!

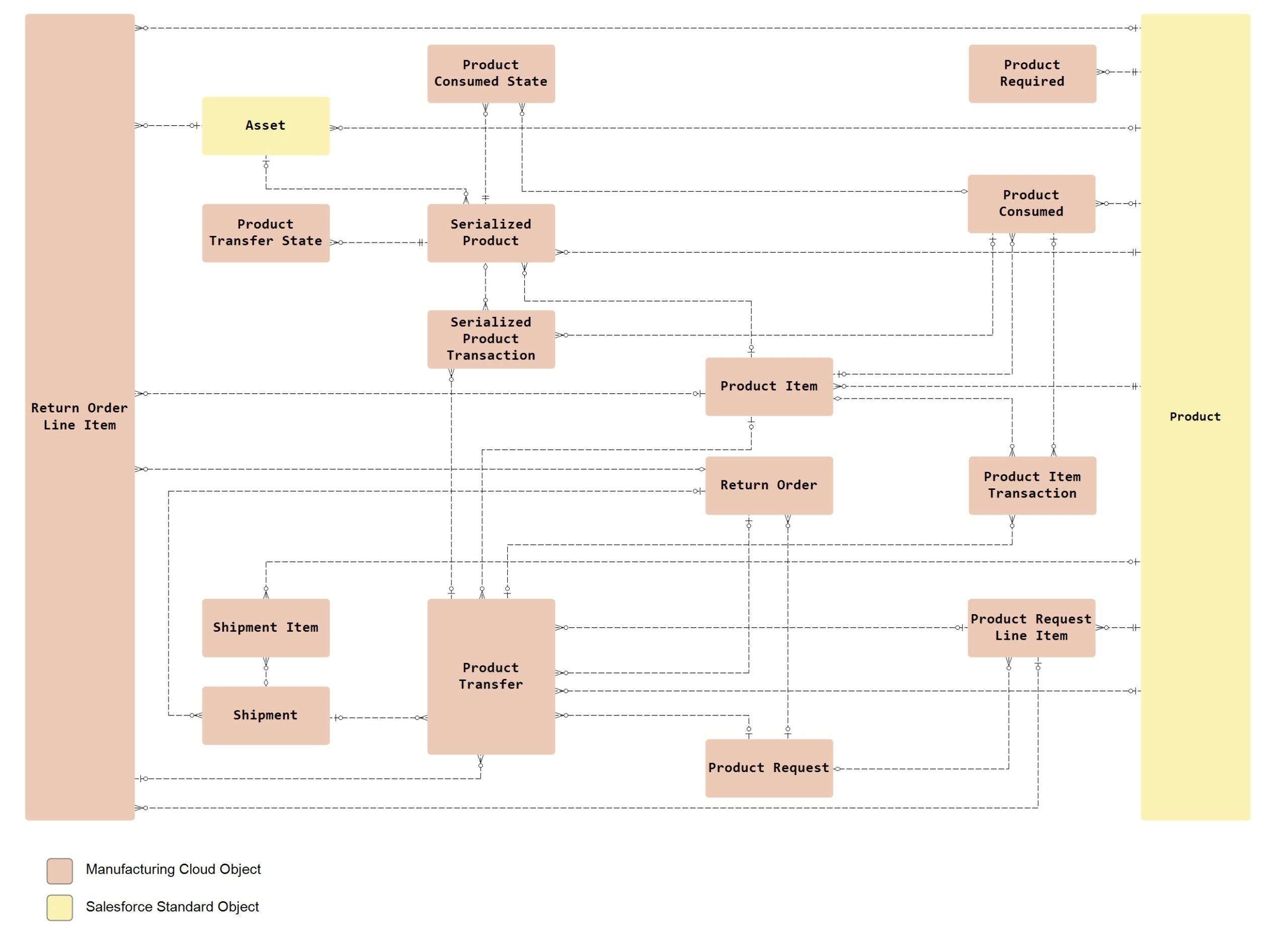

This diagram illustrates the complete lifecycle of inventory within Salesforce Manufacturing Cloud. It highlights how product items are stored, tracked, and moved between locations such as warehouses and distribution centers. The relationships between inventory transactions, shipments, product consumption, and returns are clearly visualized to help streamline inventory management and improve stock traceability.

This diagram illustrates the complete lifecycle of inventory within Salesforce Manufacturing Cloud. It highlights how product items are stored, tracked, and moved between locations such as warehouses and distribution centers. The relationships between inventory transactions, shipments, product consumption, and returns are clearly visualized to help streamline inventory management and improve stock traceability.

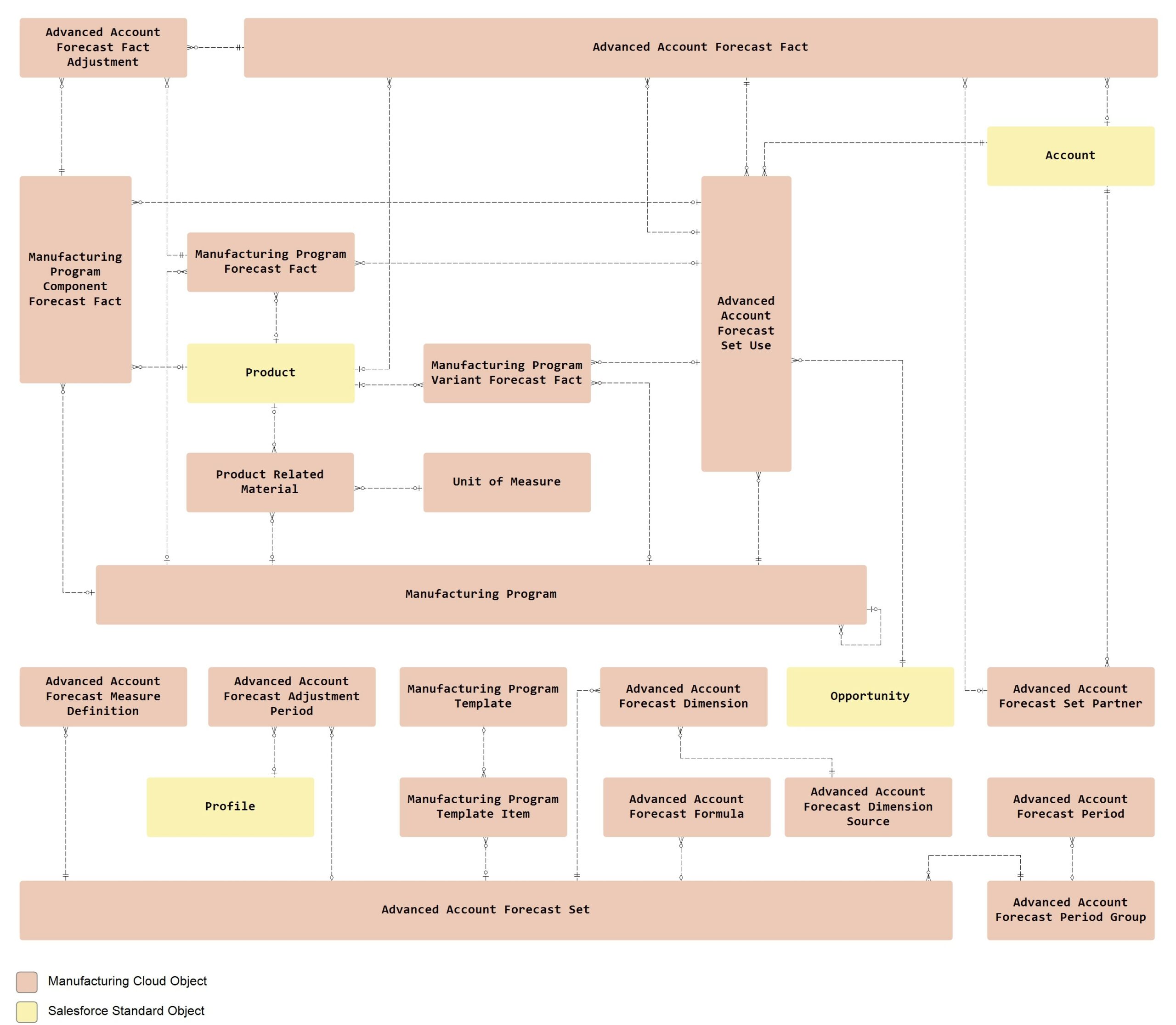

This diagram represents the Advanced Account Forecasting data model in Salesforce Manufacturing Cloud. It showcases how customer forecasts, sales agreements, manufacturing programs, and opportunities interact to provide account-specific forecasting. Key objects such as Advanced Account Forecast Fact, Manufacturing Program Forecast Fact, and standard objects like Account and Opportunity are used to predict demand accurately. This model is essential for aligning production with customer needs, managing program-based businesses, and optimizing long-term planning and resource allocation. By leveraging these relationships, businesses can derive forecasts based on customer input and manage opportunities related to specific manufacturing programs.

This diagram represents the Advanced Account Forecasting data model in Salesforce Manufacturing Cloud. It showcases how customer forecasts, sales agreements, manufacturing programs, and opportunities interact to provide account-specific forecasting. Key objects such as Advanced Account Forecast Fact, Manufacturing Program Forecast Fact, and standard objects like Account and Opportunity are used to predict demand accurately. This model is essential for aligning production with customer needs, managing program-based businesses, and optimizing long-term planning and resource allocation. By leveraging these relationships, businesses can derive forecasts based on customer input and manage opportunities related to specific manufacturing programs.

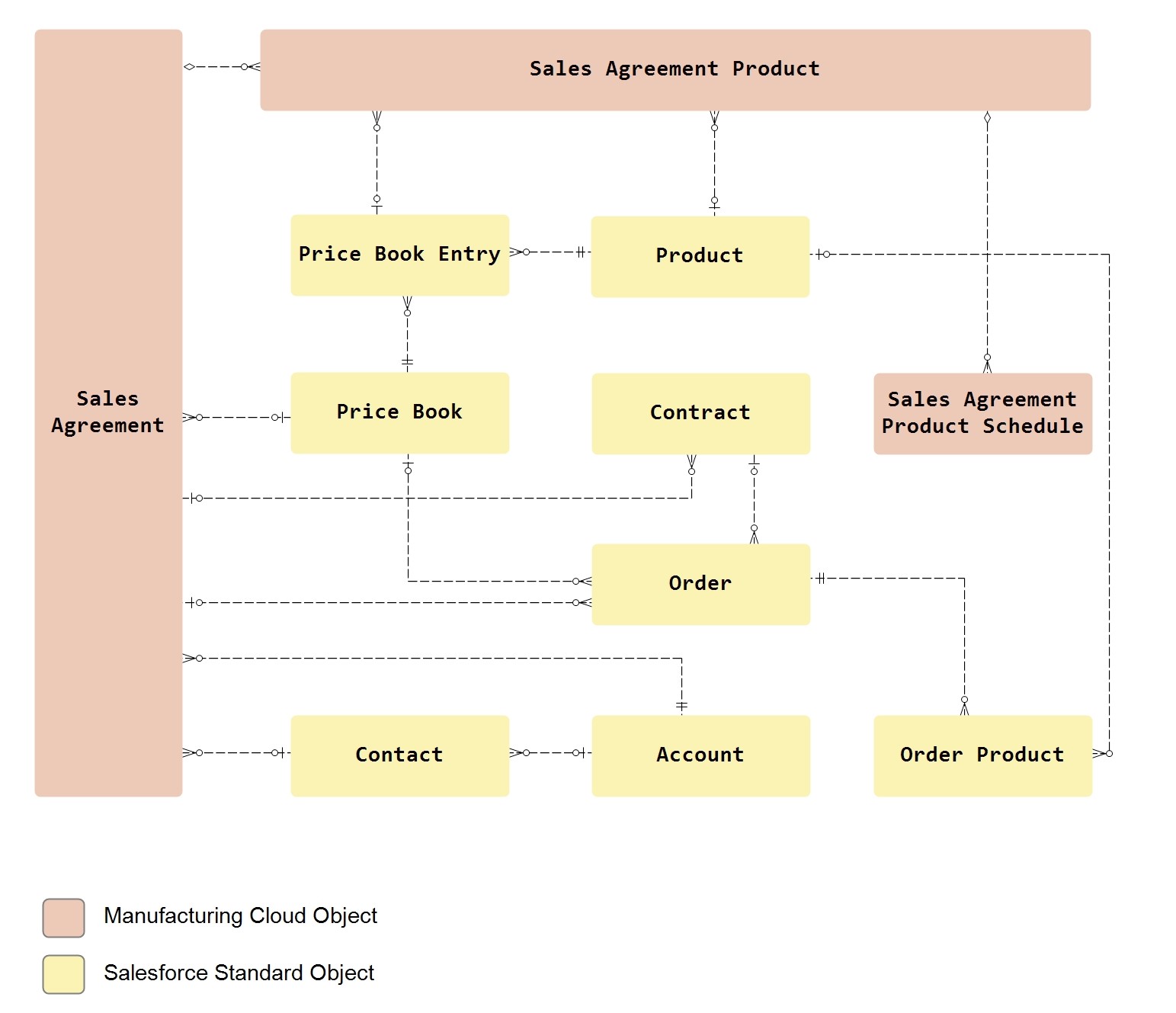

This diagram provides an overview of the sales agreements data model, mapping the relationships between sales agreements, products, pricing, and orders. It shows how sales agreements are structured over time, and how they drive sales actuals and product delivery. This model helps manufacturers maintain clarity over long-term agreements and streamline the sales-to-production pipeline.

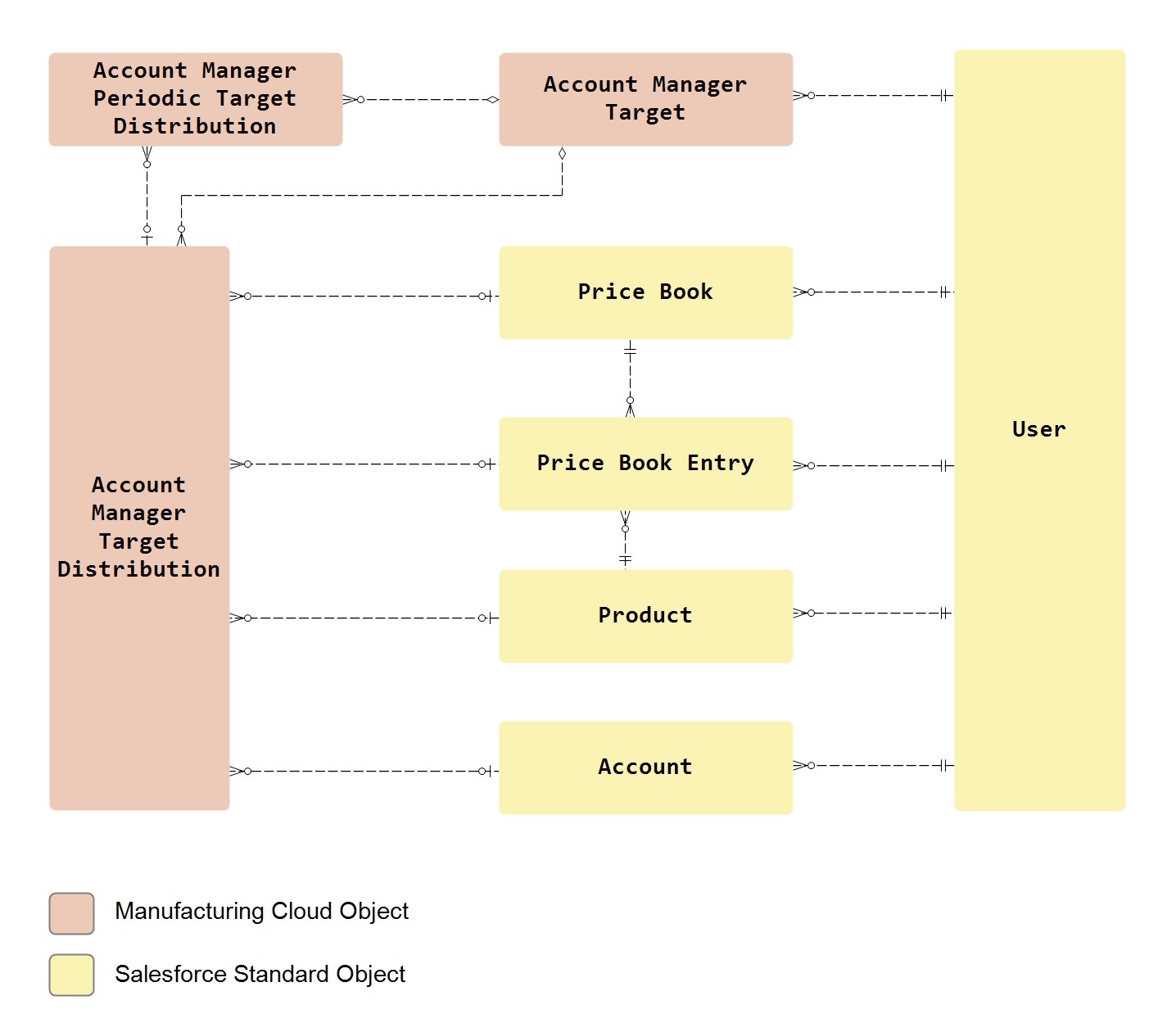

This diagram provides an overview of the sales agreements data model, mapping the relationships between sales agreements, products, pricing, and orders. It shows how sales agreements are structured over time, and how they drive sales actuals and product delivery. This model helps manufacturers maintain clarity over long-term agreements and streamline the sales-to-production pipeline. This diagram visualizes how targets are set and managed for account managers within Salesforce Manufacturing Cloud. It covers the allocation of sales and product targets across fiscal periods and shows the relationship between individual targets and overall sales goals. This model is essential for tracking performance and ensuring that team efforts are aligned with business objectives.

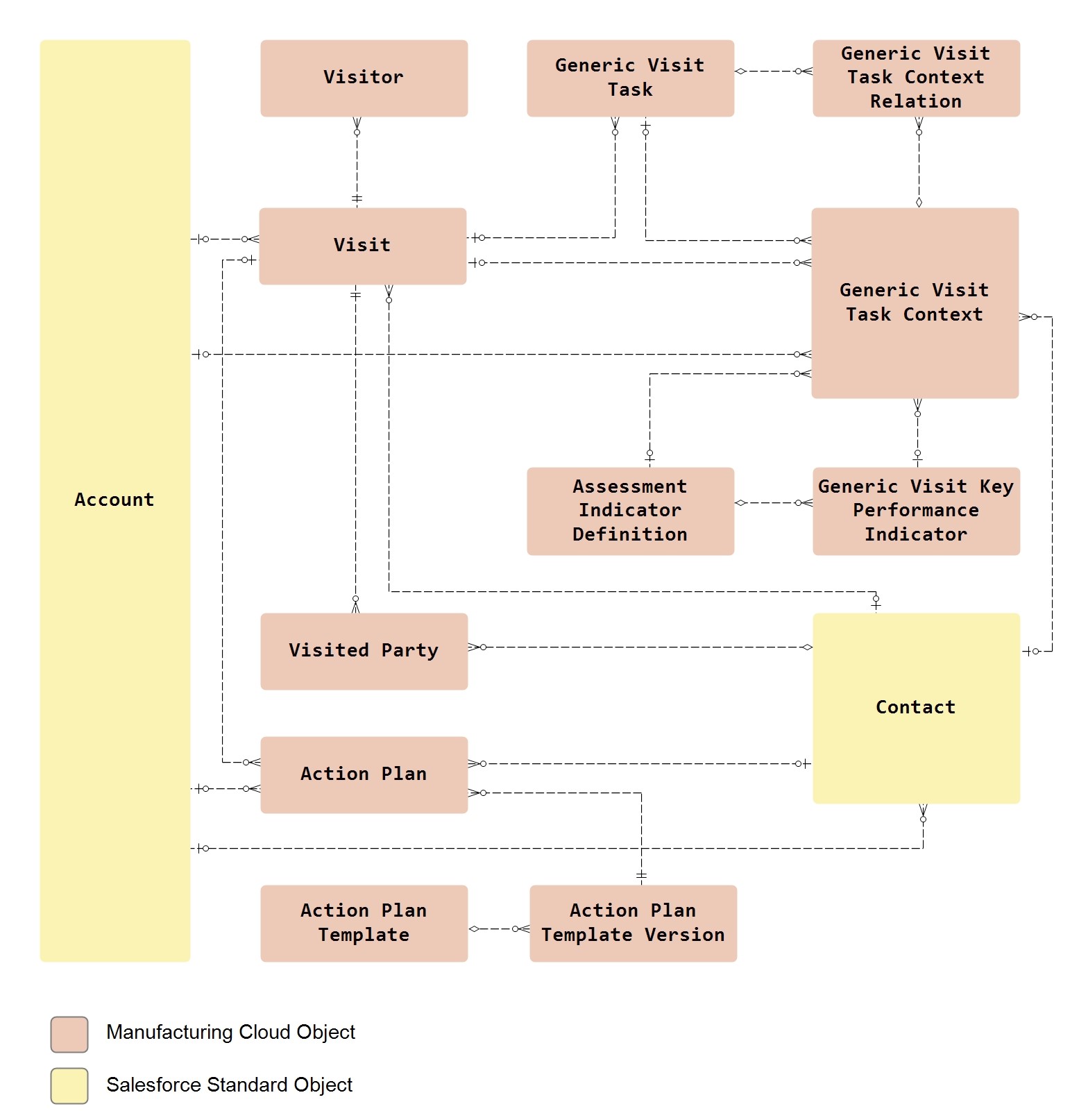

This diagram visualizes how targets are set and managed for account managers within Salesforce Manufacturing Cloud. It covers the allocation of sales and product targets across fiscal periods and shows the relationship between individual targets and overall sales goals. This model is essential for tracking performance and ensuring that team efforts are aligned with business objectives. This diagram shows the data structure for planning and executing visits to partners and distributors. It includes objects for visit tasks, action plans, and assessment indicators, helping manufacturers plan, execute, and evaluate visits. This model helps streamline field operations and improves engagement with partners and distributors by ensuring consistent follow-up and reporting.

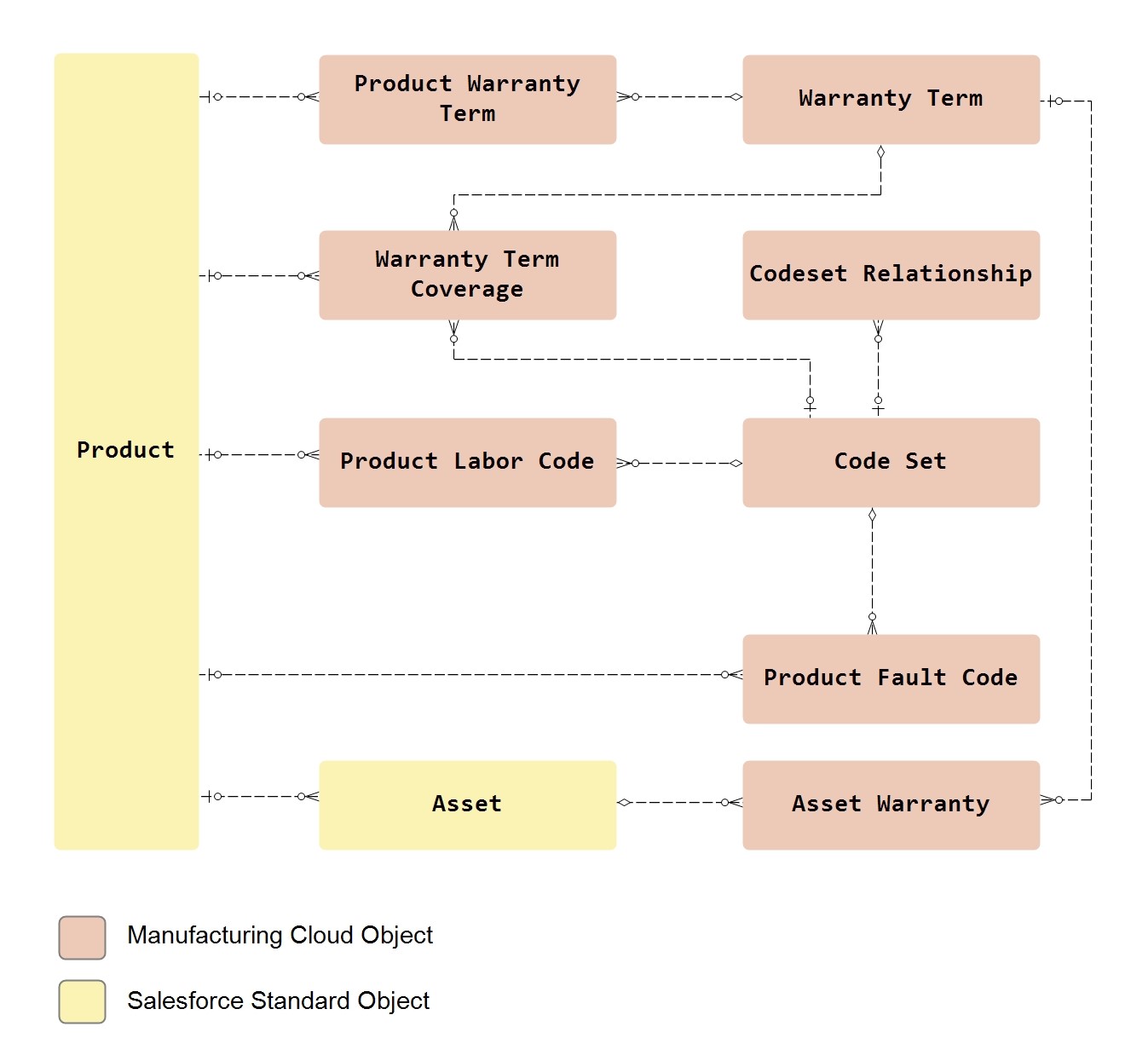

This diagram shows the data structure for planning and executing visits to partners and distributors. It includes objects for visit tasks, action plans, and assessment indicators, helping manufacturers plan, execute, and evaluate visits. This model helps streamline field operations and improves engagement with partners and distributors by ensuring consistent follow-up and reporting. This diagram represents the model for managing warranty terms and service standards across products and assets. It outlines how warranties are assigned, monitored, and linked to service cases, providing a clear view of warranty entitlements. This model ensures that manufacturers can efficiently administer warranty claims and maintain service quality standards.

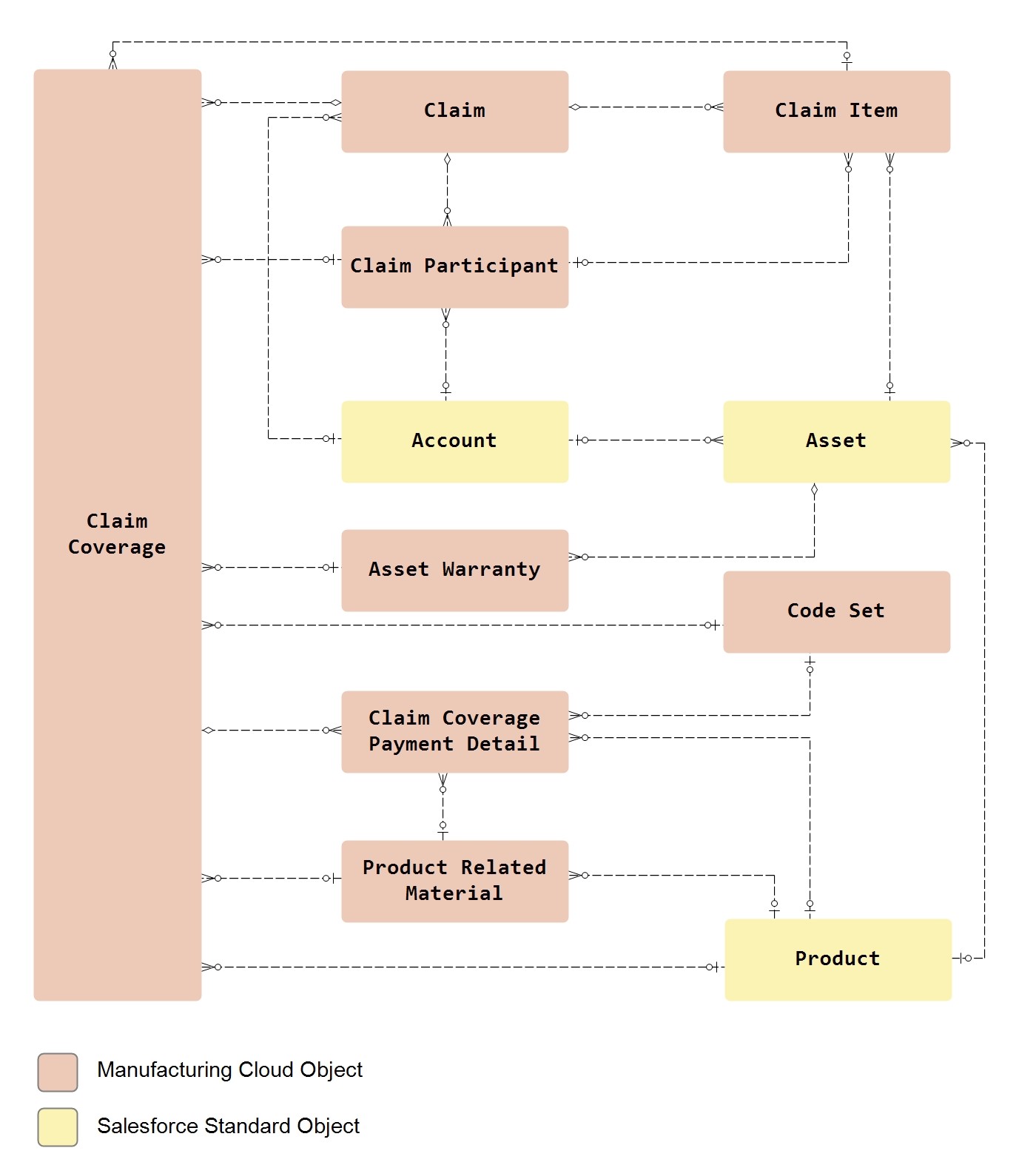

This diagram represents the model for managing warranty terms and service standards across products and assets. It outlines how warranties are assigned, monitored, and linked to service cases, providing a clear view of warranty entitlements. This model ensures that manufacturers can efficiently administer warranty claims and maintain service quality standards. This diagram illustrates the process of capturing and managing warranty claims, showing how claims are created, tracked, and processed. It details the relationships between defective assets, claim participants, and coverage details, allowing manufacturers to streamline the warranty resolution process and improve customer satisfaction.

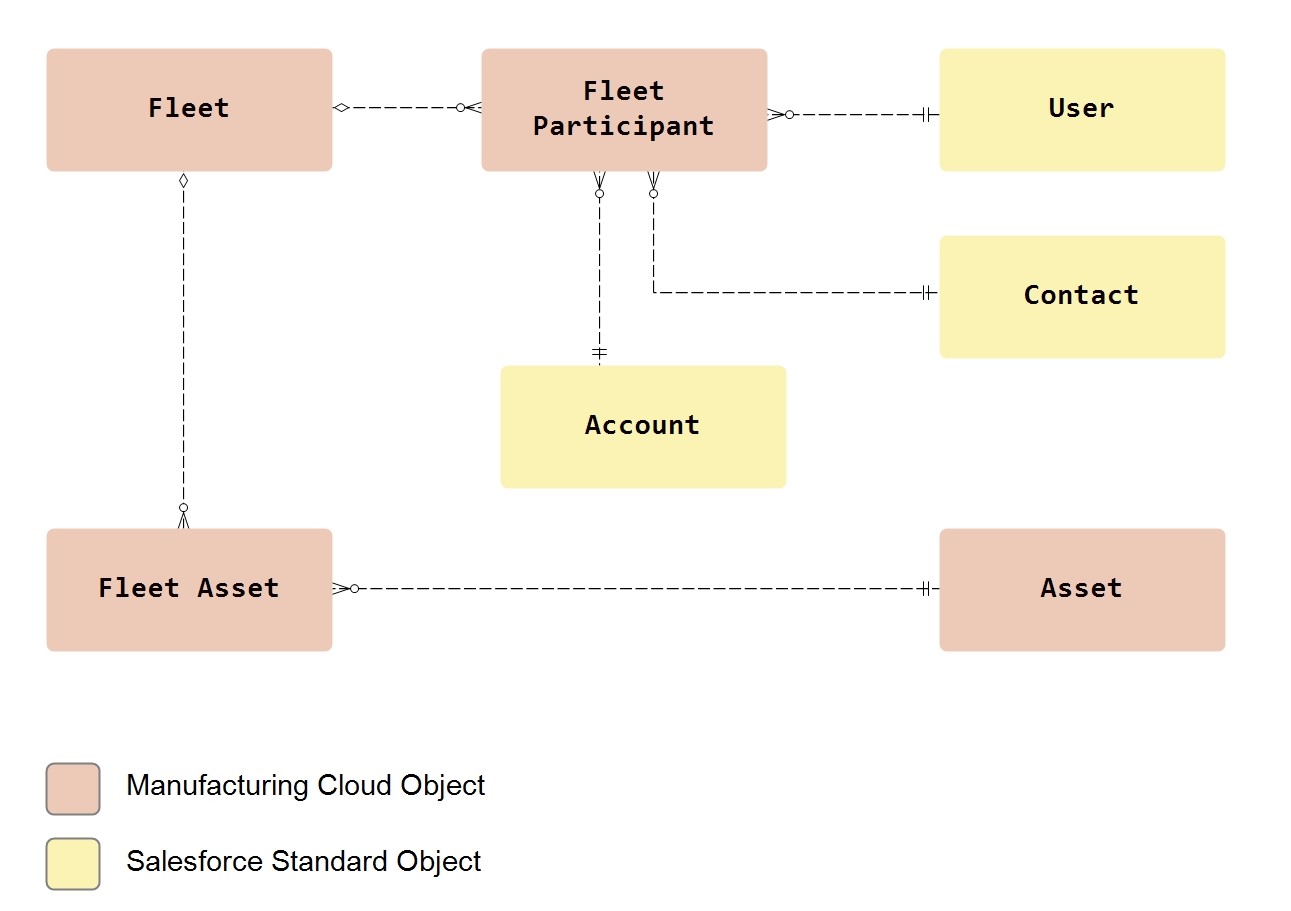

This diagram illustrates the process of capturing and managing warranty claims, showing how claims are created, tracked, and processed. It details the relationships between defective assets, claim participants, and coverage details, allowing manufacturers to streamline the warranty resolution process and improve customer satisfaction. This diagram visualizes how fleets of assets are managed within Salesforce Manufacturing Cloud, detailing the relationships between assets, fleet participants, and asset usage. It provides a clear view of asset tracking, maintenance scheduling, and fleet operations, ensuring that manufacturers can optimize asset utilization and reduce operational downtime.

This diagram visualizes how fleets of assets are managed within Salesforce Manufacturing Cloud, detailing the relationships between assets, fleet participants, and asset usage. It provides a clear view of asset tracking, maintenance scheduling, and fleet operations, ensuring that manufacturers can optimize asset utilization and reduce operational downtime.